Cathelco, part of Evac Group, is launching patented ultrasonic protection technology which protects against hull biofouling. Ultrasonic Protection (USP) DragGone reduces drag and improves fuel efficiency, reducing fuel consumption and associated emissions by up to 13%.

Biofouling is the accumulation of various aquatic organisms that gather on any part of a vessel that is exposed to sea water. This increases the drag as a vessel moves through the water, increasing the load on the engines, which in turn increases fuel costs and carbon emissions. Effective biofouling management prevents these accumulations, reducing friction and thereby reducing fuel consumption and associated GHG emissions.

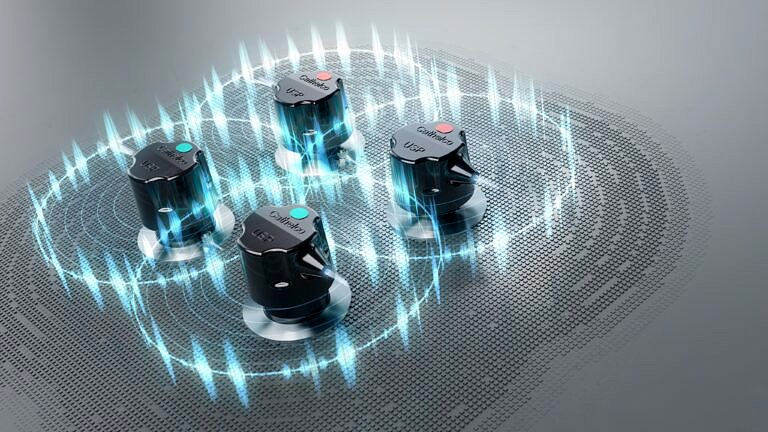

Ultrasonic protection is a proactive solution, complementary to anti-fouling paint, which ensures the hull remains clean from day one for a newbuild, or as soon as it has been cleaned for existing vessels. With DragGone, transducers are attached to the inside of the hull and emit ultrasonic waves which disrupt any kind of a biological attachment to a hull surface. They vibrate the surface, which stops the microorganisms and algae from attaching to a vessel’s hull. This also mitigates the risk of the translocation of invasive aquatic species, which has a significant ecological impact.

DragGone combines two key technical differentiators from other ultrasonic antifouling systems; guided wave and heterodyning technology – two existing and established principles, applied to biofouling management for the first time. With guided wave technology, DragGone enables the waves to travel over longer distances than traditional ultrasonic fouling solutions, which means fewer cable runs, fewer control panels, and up to 60% fewer transducers. This makes it easier to install, easier to maintain, and reduces service costs. Heterodyning generates additional frequencies, which increases range and protects against a wider range of fouling species than standard, single frequency transducers.

“The more biofouling on the hull, the greater the drag, which reduces fuel efficiency,” said Chris Hewitt, Product and Technical Manager, Cathelco. “DragGone keeps the hull clean from biofouling which can help to reduce fuel consumption, thereby reducing emissions and also costs. The IMO recognises that biofouling management is an important part of the roadmap to a decarbonised future for shipping.

“In addition, these macro-organisms can play havoc in marine habitats if they detach from the hull and reproduce in areas where they are non-native. While much effort has gone into ballast water treatment over the past decade, hull and niche area biofouling is also a key contributor.”

“Hull cleaning is a reactive solution to biofouling management – if you have fouling on the hull you will have suffered from the effects of drag before it is cleaned, thereby impacting fuel efficiency,” added Dr. Sasha Heriot, Product Development Business Manager, Cathelco. “Hull cleaning is an expensive process with a possibility of coating damage, either during regular dry docking when the vessel is taken out of service, or by using cleaning robots, or divers, which has potential safety implications. With DragGone, the hull remains clean from day one, preventing even a fouling slime layer from forming, which is what creates an environment for barnacles and other macrofouling to form.”

Cathelco’s antifouling systems are already installed on over 25,000 vessels worldwide. These marine growth prevention systems (MGPSs) are volume treatment systems for the protection of sea chests, internal pipework and box coolers.

With cathodic MGPSs, copper anodes are fitted at the sea water intakes. They create an environment the organisms dislike and discourage marine life from settling inside the pipework. Ultrasonic protection is better suited to surface treatment, such as the hull. MGPSs protect against macrofouling, such as barnacles and mussels, but this new ultrasonic system is effective in protecting at an earlier stage, against microfouling.

DragGone joins Cathelco’s full suite of products for vessel protection from biofouling, with MGPS, impressed current cathodic protection (ICCP) technology – which reduces maintenance costs by preventing corrosion on ship hulls and offshore structures – and now ultrasonic antifouling.