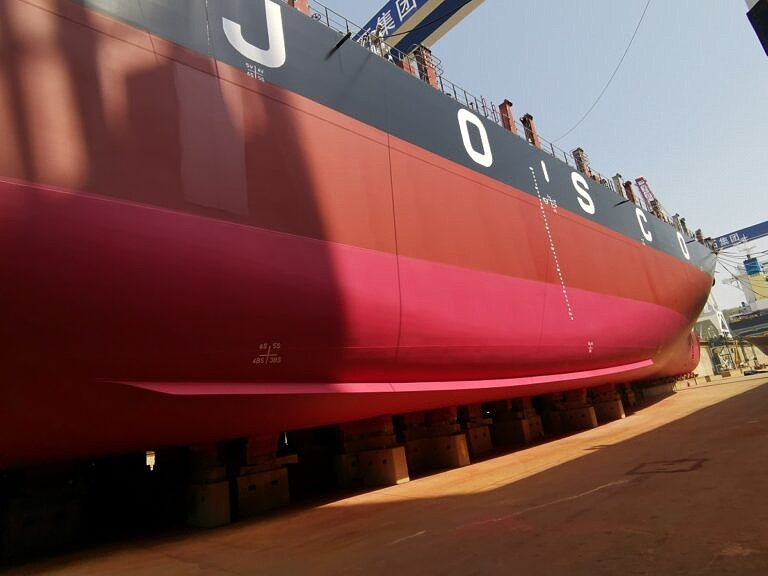

Nippon Paint Marine’s ground-breaking nano-based antifouling FASTAR I® has been selected for the trio of energy-efficient box ships the Tsuneishi Group is building for China’s Jiangsu Ocean Shipping Co (JOSCO).

The first 1091TEU ship in the series, Hull No SS297, is nearing completion at the shipbuilder’s facility in Zhoushan City, Zhejiang Province, China, and scheduled to join the JOSCO fleet last month (April). The second and third vessels in the series will be followed in August and September retrospectively.

With an overall length of 146m and a 23.25m beam, each vessel in the series is based on Tsuneishi’s innovative low-resistance hull form and includes an array of energy-saving technologies.

Commenting on the decision to apply the FASTAR coating, Lian Jian Guo, General Manager, Technical Division, JOSCO, said: “We have very good experience with Nippon Paint Marine systems on our vessels, so were keen to add to the overall energy efficiency of these next generation vessels with the new FASTAR system. With the installation of advanced technologies designed to reduce energy consumption and emissions, these vessels will be the greenest in the JOSCO fleet.”

The advanced technologies to which Lian Jian Guo refers include Tsuneishi’s ‘TOP-GR’ and ‘MT-FAST’ systems, of which the former optimises the number, diameter, shape and geometric distribution of propeller blades to achieve greater propulsive efficiency. Further efficiency gains are achieved with MT-FAST’, which adds a wing-like device to the front of the propeller to alter water flows.

“The application of these two technologies combined with FASTAR is expected to contribute to significant fuel savings and help us meet environmental standards,” he said.

Gerald Mao, Senior Director, Nippon Paint Marine (Shanghai), furthered: “JOSCO’s experience with our LF-Sea® and A-LF-Sea® antifouling systems has delivered fuel savings of up to 8%, which can equate to a voyage free of fuel costs every twelfth trip or so. We anticipate FASTAR will deliver further cost savings and environmental efficiencies.”

Introduced to the market early last year, Nippon Paint Marine’s fourth generation antifouling uses completely new hydrophilic and hydrophobic nano-sized silyl acrylate components to more precisely control the release of biocides.

“It is by precisely controlling the release of biocides that we have been able to deliver a high-performing, low-polishing antifouling system that not only delivers unprecedented commercial benefits but also helps shipowners and operators meet emissions abatement and energy efficiency targets,” said Mao.

“Liner operators like JOSCO are facing increased congestion at port with at least 30-day waiting times so need a coating that delivers consistent 60-month performance unaffected by seawater temperature and vessel speed.

“FASTAR I has been designed to deliver optimum performance and save fuel after longer idling times, when conventional coatings experience increased biofouling,” he said.

Tsuneishi group (Zhoushan) Shipbuilding, one of Japan’s Tsuneishi Shipbuilding Co., Ltd’s overseas shipyards, is also building three similar 1091TEU vessels for Taicang Container Lines Co., LTD, a subsidiary of China’s Jiangsu Port Group. These vessels, designed for the intra-regional trade, will also benefit from the FASTAR coating.

Commenting on the performance benefits, Jun Ye, M & R Sales Director, Nippon Paint Marine (China), said: “For a containership with 80% activity, operating at 18kts in seawater temperatures of 26°C, a FASTAR scheme provides 60 months of service from a dry film thickness of 260µm on the vertical sides and a 160µm coat of on the flat bottom. A conventional antifouling covering the same 2000m2 area would require 1018 litres of paint versus 1330 litres.

“We are delighted that Tsuneishi Group’s next generation of energy efficient box ships are being specified with FASTAR. It’s a win-win coating for owners and builders,” concluded Jun Ye.